Palletizing is the act of stacking products onto a wooden (or plastic) shipping pallet for transport. Depalletizing is the unloading of these products at the destination. Palletizing is a relatively simple application for a robot to accomplish, as it involves minimal variation. Depalletizing is more complex and typically involves machine vision and sophisticated end effectors.

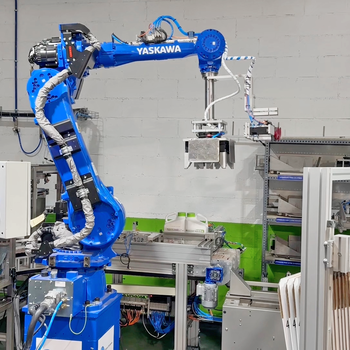

Yaskawa Motoman offers manufacturers a wide range of robotic solutions for palletizing and depalletizing. When using flexible robotics with 2D and 3D vision systems, specialized software and tooling enable you to customize your shipping and receiving without sacrificing speed and accuracy.

Более чем 100-летний опыт технического прогресса позволил нам стать ведущим производителем в области частотных преобразователей, сервоприводов, систем управления и робототехники.